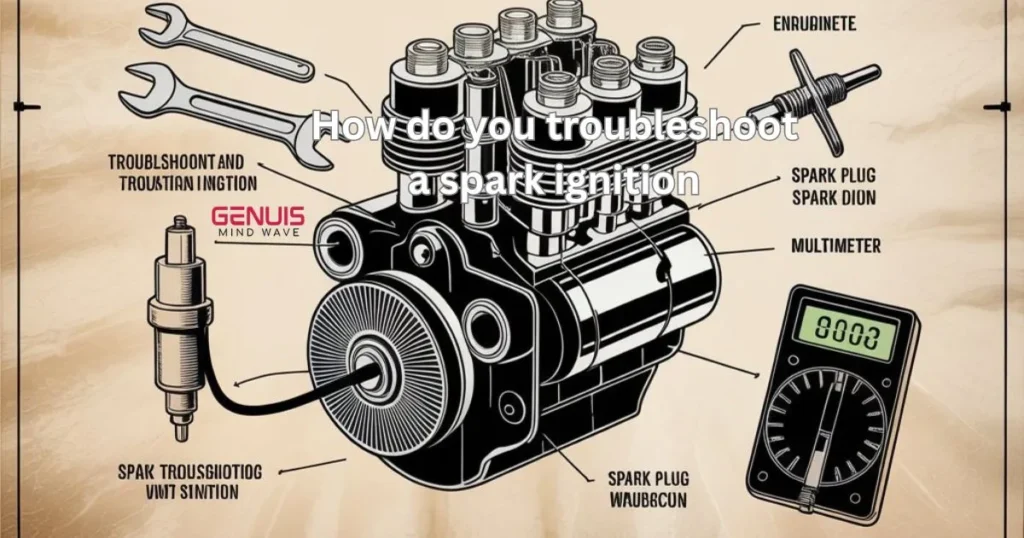

First, how do you troubleshoot a spark ignition system when it suddenly fails? The answer starts with careful inspection and testing of the procedure. This process applies regardless of whether the issue is a pilot light failure or inconsistent performance in a boiler ignition system.

This process involves checking key components like the spark plug, coil, and control module. There could be issues with the continuity of the ignition cable or a malfunctioning ignition control module.

Identifying these problems requires basic tools like a multimeter. Understanding the symptoms—like a weak ignition spark or ignition delay—can help you take action before the system fails. With routine maintenance and smart diagnostics, you can troubleshoot most furnace spark problems with confidence and clarity.

In this article, you’ll learn everything you need to know so you can troubleshoot your problem yourself without anyone’s help. So let’s find out how we can help you.

What Is a Spark Ignition System?

A spark ignition system is used in gas-fired appliances to ignite the burner. It replaces old pilot lights with controlled electric sparks.

This method of ignition is common in modern boiler ignition systems and furnaces.

The system includes a few key components. The spark plug creates the spark. The ignition coil increases the voltage.

The distributor or ECU manages the timing.

The battery and wiring provide the electricity.

These parts work together to safely and efficiently ignite the fuel and air mixture.

What Are the Advantages of How Do You Troubleshoot a Spark Ignition?

Furthermore, understanding how to troubleshoot spark ignition offers practical benefits. You can quickly identify problems such as pilot light failure or weak ignition spark without the need for immediate professional help.

This helps reduce downtime, improve engine performance, and avoid costly repairs.

By learning HVAC ignition diagnostics, you also gain confidence in handling equipment such as boiler ignition systems or furnace spark problems.

Early detection through steps such as continuity testing with an ohmmeter can prevent a full-blown spark condition, ultimately saving both time and money.

.

How can spark ignition be damaged?

However, various factors can cause spark ignition devices to fail. An engine can fail due to some broken parts.

Such as,

an ignition control module that has shorted out, a spark plug that has worn out, or links that are corroded.

Wet or dirty connections can cause them to break, reducing their performance.

Excessive heat can also weaken the internal circuits in the ignition module.

In some cases, the continuity of the ignition cable is broken due to physical wear or ignition cable outgassing, which impairs signal return.

To prevent serious damage, it is important to inspect the system regularly.

Learning how to properly troubleshoot spark ignition can help detect these problems early, especially using tools like an ohmmeter or performing a spark-to-ground test.

How to Protect Spark Ignition Systems from Damage

Furthermore, keeping your ignition system safe starts with regular maintenance. Clean the ignition cable ends.

Check for outgassing of any ignition cables, and make sure no moisture is entering the system.

Avoid placing components near heat sources to prevent damage to the ignition control module.

It is also smart to secure proper ground connection issues, as poor grounding can cause misfires or complete failure.

Learning how to properly troubleshoot spark ignition includes preventative measures such as checking connections, replacing cracked spark plugs, and verifying continuity with an ohmmeter.

Following these practices will help extend the life of your ignition system and keep it running safely.

Common Spark Ignition Problems

Now, let’s explore:

What could be wrong?

Problems can manifest themselves in many forms. Your engine may not start at all or may misfire.

You may hear or see the engine running rough. Poor performance often indicates a weak ignition spark, bad parts, or ground connection problems.

Other symptoms include reduced fuel efficiency or a soft lockout system, which shuts off the ignition after unsuccessful attempts.

These problems should be diagnosed early to avoid a complete lockout of the heating system.

Tools Needed for Troubleshooting

Before you begin the repair, gather the necessary tools.

These tools are essential for inspecting components such as

the ECU,

the coil,

or the ignition wire.

You will need four tools to do this:

a timing light,

a voltmeter,

and a spark plug tester.

Remember to wear gloves and safety glasses.

These protect you during the high-voltage test and mechanical check.

Step-by-Step Troubleshooting Guide

Once your tools are ready, it’s time to double-check every part. This section covers the core of HVAC ignition diagnostics.

Check the Spark Plugs

Start with a visual inspection of the ignition system. Remove the spark plug and examine its tip. If it’s black or burnt, clean it or replace it. Also, check the spark gap distance. If the gap is off, it may prevent proper ignition.

Test the Ignition Coil

Now, use a multimeter to check the coil resistance. This tells you if the electricity is flowing properly. Faulty coils often lead to a weak ignition spark. If resistance is too high or too low, replace the coil.

Inspect the Ignition Control Module

Check the ignition control module or ECU next. Look for loose wires and read any error codes. These often reveal problems in the sequence of operations. A damaged module may need an ignition module replacement.

Check Battery Voltage

Measure battery power with your multimeter. It should be at least 12.6 volts. If it drops too low while cranking, ignition can fail. Bad batteries result in poor spark performance or no spark condition.

Test for Spark

Use a spark plug tester here. Crank the engine and watch for the arc. A good spark should jump at least ½ inch. The arc checks the ignition spark intensity and identifies if your spark system is even working.

Check Timing

Finally, connect a timing light and verify ignition timing. If the timing is off, fuel may ignite too early or too late. Adjust timing settings according to your system’s manual to fix this.

Preventive Maintenance Tips

A poor chassis ground connection causes many issues. Dirty or painted surfaces can block proper grounding. Use a wire from the module’s green terminal to a clean metal surface. This procedure ensures your spark-to-ground test works reliably.

Prevent Grounding and Wiring Issues

A poor chassis ground connection causes many issues. Dirty or painted surfaces can block proper grounding. Use a wire from the module’s green terminal to a clean metal surface. This step will make sure that your spark-to-ground test always works.

Final Checks and Wiring Polarity

When you’re done, double-check the 24V transformer wiring. There should be 24 V on the “R” terminal and ground on the “C” connector. A polarity check on a transformer ensures safe operation and prevents shorts.

If needed, examine your transformer voltage to the ground with a multimeter. Reading both terminals helps avoid wiring mistakes that can destroy components.

Ignition System Rules & Safety Notes

Always follow key safety rules when replacing parts. For example, during a time trial for ignition, you can use a module with less time but not more. Also, you can extend the pre-purge and post-purge cycle to improve safety. But never shorten them.

Check for features on the starting module that can fix themselves if the system fails. These allow retries without needing to reset power. And remember—proper setup avoids heating system lockout.

Troubleshooting Flame Failure and Gas Flow

To address flame failure issues, inspect your gas valve and ensure it opens correctly. Use gas control diagnostic tools. Also, the inducer motor operation must be checked to clear gases before and after ignition.

When in doubt, always go back to your wiring diagram. Follow the electrical troubleshooting steps and test each circuit with care.

Conclusion

Learning how to troubleshoot a spark ignition system gives you control and confidence. Whether it’s a pilot light failure, ignition cable outgassing, or a complex wiring fault, knowing what to search for helps you act fast. Use this guide as your go-to checklist for spark ignition troubleshooting. Your system will stay safe, reliable, and efficient as long as you do regular upkeep and smart testing.