Laser engraving has revolutionized how we create intricate designs and personalize products. No matter if you are an enthusiast small-business owner or part of a more extensive production line, laser engraver machines could prove indispensable in helping make intricate designs or personalizing items for sale. But with so many choices out there, it may be unsafe when trying to select an engraver laser machine. To help guide you in the selection process further, this post outlines additional characteristics worth looking out for in an engraver laser machine that ensure that you find precisely the best-fit solution tailored specifically for you and your specific requirementsLaser Engraver Machine .

1. Type of Laser

The type of laser being utilized with engraving machines should be one of the key considerations when purchasing one, with three of the most frequently chosen models including:

CO2 lasers are highly adaptable laser systems and widely utilized by both amateurs and experts alike, being adept at cutting through materials like wood, acrylic, leather, and some metals, as well as producing even finishes with precise designs for projects of various materials such as glass and wood. CO2 lasers make an excellent addition to any creative endeavor when looking to craft projects with even finishes and precise designs.

Fiber Lasers

Laser Engraver Machine Their precise cutting abilities and Speed make them suitable for industrial processes, including marking objects using barcodes or engraving intricate designs onto metallic surfaces.

Diode lasers,

Laser Engraver Machine smaller and less powerful lasers that cut soft materials such as wood, leather, and plastic with ease, are typically preferred by beginners or for smaller-scale projects. They make cutting soft materials faster while leaving minimal debris behind when finished cutting them. These models provide an excellent starting point and solution.

Selecting the ideal laser is crucial. If your primary concern is engraving nonmetallic materials,

CO2 lasers

may be most suitable; Otherwise, if metalwork needs are involved, fiber lasers could provide optimal solutions.

2. Laser Power

Laser Engraver Machine A laser’s power, measured in watts, determines its ability to cut through or inscribe materials efficiently, and this affects efficiency as a measure. This also shows how its levels impact efficiency:

Lower Watt (20–40 Watts) Laser:

Suited for soft engraving materials like leather, wood, or acrylic. Low-power lasers work effectively at precisely engraving thin materials but may struggle with thicker substances.

Medium power (40–60 Watts):

Laser Engraver Machine Provides an ideal combination of engraving and cutting capabilities. Lasers at this power level can work with various substances and are suitable for most hobbyists as well as small-scale businesses.

High-Power (60–150 Watts or higher) Lasers:

Intended to meet industrial usage requirements, high-power lasers are used for cutting through more dense materials as well as engraving surfaces such as stone and metal surfaces. Due to being more energy-efficient, lasers with such power levels make ideal production solutions on a large scale.

Selecting an optimal power level is of vital importance when producing intricate designs or simple engraving. A lower power consumption might suffice, but for thicker materials or faster speeds of production, a greater wattage might be needed.

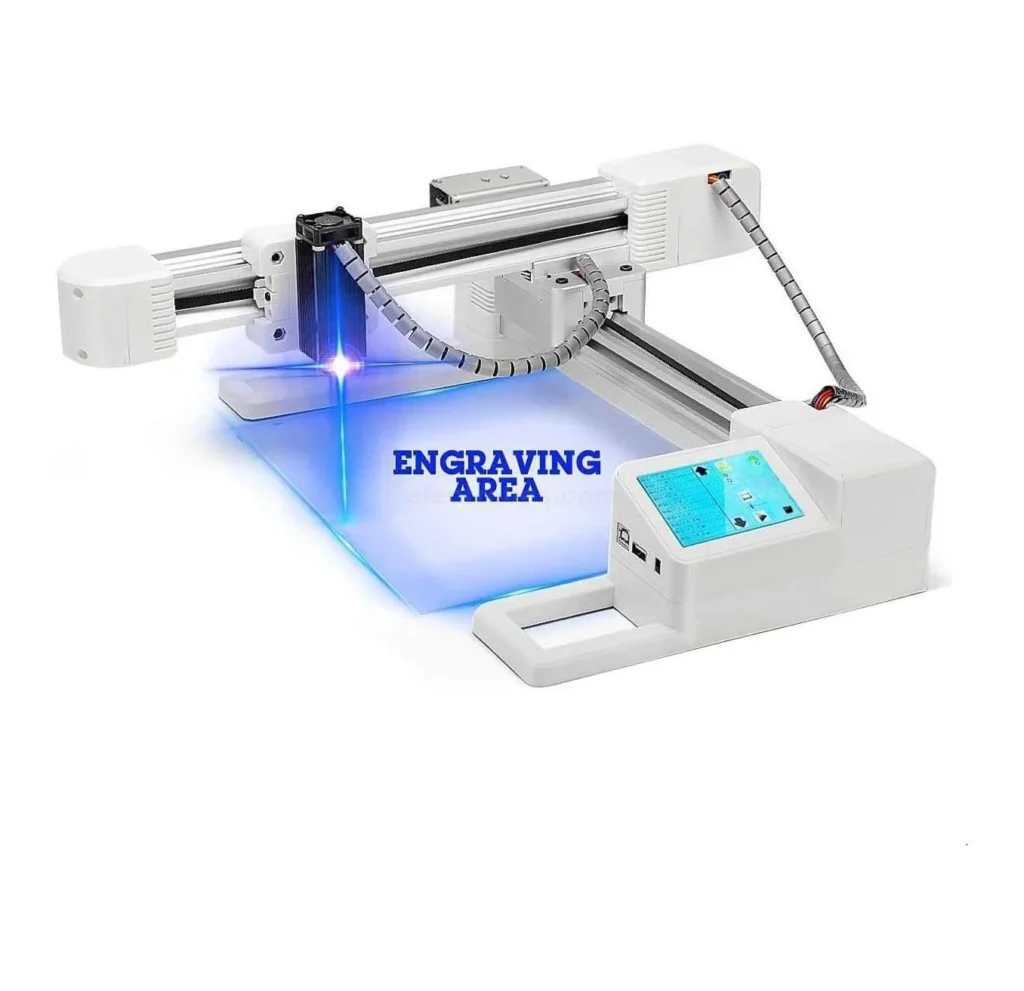

3. Work Area Size

Your work area size (also called bed engraving dimensions ) will determine which materials can be worked with in engraving projects. Consider these aspects before choosing yours:

Small Work Space (Up to 12″ x 8″)

A smaller work area machine is ideal for engraving small things such as keys, jewelry, or gifts with custom engraving designs. Machines with smaller work areas tend to be suitable for those seeking a hobby with limited available space.

Medium Work Space (up 24-in x 18-in)

Ideal for projects of medium size, such as signage, plaques, or more complex custom pieces that need ample work area and flexibility for assembly, such as signs or plaques. They provide both space and versatility.

Ample Work Space (24″ x 24″):

explicitly built for industrial use, these large workspaces offer ample room to store large sheets of materials as well as accommodate intricate layouts for mass production or signage projects.

Choose a size suitable to the nature of your project when choosing your workspace size. For engraving large items simultaneously or working with numerous objects simultaneously, a larger area may prove beneficial; otherwise, smaller machines might offer better solutions.

4. Accuracy and Resolution

Resolution and precision are two critical aspects that influence engraving quality. Machine precision can be measured using the laser’s movements, while Resolution refers to the finer details the laser can reproduce – it is measured as dots per millimeter (DPI).

High Performance (+0.001″ or Higher):

Perfect for detailed engraving projects such as intricate designs, delicate words, or tiny logos requiring high-precision equipment that ensures even minute details remain clear and sharp.

High Resolution (500 DPI or More):

Ideal for precise engraving projects such as photo engraving and those that demand smooth, precise finishes with soft surfaces, such as photo embossing.

Most applications require accuracy within +-0.001″ for optimal results, so 500 DPI resolution could provide great returns. If your work involves ultra-precise details, however, consider investing in a device that offers even higher precision and resolution capabilities.

5. Speed and Efficiency

To measure laser engraving machines’ speeds accurately, two methods should be utilized: engraving speeds as well as cutting speeds. Higher engraving and cutting speeds improve efficiency for industrial uses in particular.

Faster Engraving can be measured in inches/second (IPS).

Faster engraving works well when producing multiple items quickly but may reduce quality, so striking an effective balance between quality and Speed should always be considered when running any business.

Cutting Speed,

In addition to being determined by IPS, it can also depend on both laser power and material thickness; higher speeds may prove helpful when cutting thick materials requiring multiple cuts at different depths.

Speed controls on well-qualified or industrial application equipment are ideal if you want to maximize both efficiency and quality; hobbyists may prefer quality over Speed in projects requiring fine details.

6. Software Compatibility and Attributes

Laser engraving machines feature software that significantly facilitates their user-friendliness and adaptability for various users, with this piece of technology having an enormously positive effect.

UX When selecting programs for laser engraving, choose ones that are intuitive and user-friendly, especially if this is your first experience with it. Software that facilitates drag-and-drop and design processes will make using them more straightforward while decreasing learning times significantly.

Design Flexibility The program should support multiple file formats (AI, SVG, DXF and PDF) while offering advanced design tools to facilitate creating or editing designs right within its application.

Check Compatibility With Design Software:

Certain software offers features such as vectorization of layers, management of layers and real-time engraving simulation that can enhance both the designing process as well as ensure precision when engraving the final item. Having these tools available will streamline and expedite this step in the production cycle.

Select a laser engraving machine that suits both your skills and requirements for design. Users with advanced talent may appreciate programs offering more control, while beginners could prefer something with a more straightforward user interface.

7. Material Compatibility

Lasers can be used with numerous kinds of materials. Therefore, understanding if and how each laser fits with those materials is essential in making sure it can fulfill all your specific project needs.

A flexible laser engraving machine can handle many materials such as wood, acrylic fabric, leather, glass, and metals – an invaluable advantage for those dealing with various materials. This makes a multi-use engraving machine especially handy.

Specialized machines If your work involves specific kinds of material such as glass or metal, such as fiber laser engraving on metal and CO2 laser cutting on nonmetallic material, respectively, specialized machines should be considered accordingly. Fiber lasers tend to work better for metal engraving, while CO2 lasers offer reliable nonmetallic laser solutions.

Adjustability Discover machines that permit you to tailor the Speed and intensity of the laser depending on the material to achieve optimal results with every material type. This guarantees perfect outcomes no matter what material type it comes to be processed.

Finding a laser engraving device compatible with your material requirements will increase both the efficiency and the performance of your work.

8. Cooling System Laser engraving

creates heat,So a proper cooling system is vital to maintaining both the efficiency and longevity of this type of Machinery.

Water cooling systems have long been utilized in high-powered lasers as an effective means to manage heat emissions generated during operation, making this type of solution perfect for continuous, high-intensity use.

Air Cooling for Less-Powerful or Less-Compact Equipment Air cooling systems

may not be suitable for long-term usage in higher power or more compact equipment, as their simplicity does not provide efficient cooling capabilities.

Temperature Monitoring Modern machines feature integrated temperature sensors

that measure laser temperatures and adjust their cooling systems accordingly to avoid overheating.

Reliable cooling systems ensure the laser machine functions efficiently while also prolonging its lifespan, which are essential qualities in professional users with experience in using laser machines.

Laser engraving equipment can be dangerous to use improperly;

Therefore, safety precautions are of vital importance.Protective Enclosures Most engraving machines

feature enclosures that offer protection from laser exposure while at the same time containing fumes and particles released when engraving takes place, helping both user safety and creating an environmentally-

safe workplace. Such enclosures serve two essential purposes – user protection as well as providing cleaner environments.

Emergency Stop Button A simple emergency stop button allows users to stop the machine in case there is any issue immediately or there is something amiss with it.

Check that all equipment meets industry safety requirements and has the necessary accreditations,

providing assurances that it has been thoroughly assessed for compliance. This helps guarantee safe operations from your equipment purchase.

Filtration and Fume Removal:

Laser engraving can generate fumes when working with certain materials, so an ideal machine must

include or work alongside an air filtration device that removes dangerous particles from the atmosphere.

Security should never be compromised, so select a machine that prioritizes this aspect

through features that offer strong user protection and safeguards.

10. Construct Quality and Durable Construction Projects

Quality construction plays a huge role in the longevity and reliability of laser engraving equipment.

Solid frames constructed of materials such as aluminum and steel offer greater endurance and stability,

helping ensure consistent engraving quality over time. A sturdy construction machine also helps eliminate vibrations for greater comfort during operation.

Quality Components When searching for machines with quality lenses, motors, and mirrors that will directly contribute to the performance and lifespan of the machine you select, pay particular attention. They play an essential part in its function and longevity.

Support and WarrantyDimensiuni A long warranty shows confidence in a product from its maker;

additionally, consider access to customer support as well as parts/Service centers in terms of support available to customers and parts availability.

An impressive machine construction ensures it can withstand daily usage while operating at peak performance over its life.

11. Simplicity of Maintenance

Maintenance is crucial to keeping your laser engraving machine operating at optimal levels

, so be sure to choose an ease-of-maintenance model for optimal operation.

Accessibility of Components Machines that enable easy access to critical elements like laser tubes

and lenses make tasks like changing or cleaning parts much more achievable.

Automated Maintenance Alerts Certain advanced devices come equipped with sensors that notify the user when maintenance, such as alignment or cleaning of lasers, is needed.

Repair Parts: Access and Affordability

Spare parts must be readily available and affordable if they are to reduce downtime and ensure smooth machine operations. Equipment that has been specifically designed with maintenance in mind will save time while decreasing repair costs in the future.

12. Comparison and Value for Money.

Pricing should reflect both its capabilities and your budget constraints when looking for laser engraving machines.

Cheap machines,

typically priced under $500, are suitable for hobbyists or beginners looking for something simple yet powerful to start their machining careers with.

While they are easier than their more advanced counterparts and feature-packed counterparts, these cheaper models may lack certain advanced functions or power requirements.

Mid-range computers

priced from $500 to $3,000 provide an ideal combination of capabilities,

power, and high-end construction – ideal for smaller enterprises or those serious about their hobby.

High-End Machinery

\comes at a cost of more than $3000 and features the most excellent power, accuracy, and quality construction available today.

They’re intended for skilled or industrial uses alike and should meet those looking for accurate efficiency and longevity in a machine.

As part of your cost evaluation, be mindful to factor in its long-term worth.

A higher initial price justifies itself through lower maintenance expenses and increased efficiency,

as well as a greater life span and longevity.

Conclusion

Laser Engraver Machine Finding an ideal laser engraving machine involves careful consideration of numerous features,

including laser type, power consumption, build quality, and safety functions.

By paying close attention to these critical areas, you’ll be able to select an engraver that suits both your current needs and adapts well to your plans.

The purchase of a laser engraving machine can be an exciting,

life-altering decision, whether for amateur use or business production capability improvement. When choosing the appropriate machine, accurate, high-quality engravings that stand out will result in unforgettable artwork in today’s marketplace.