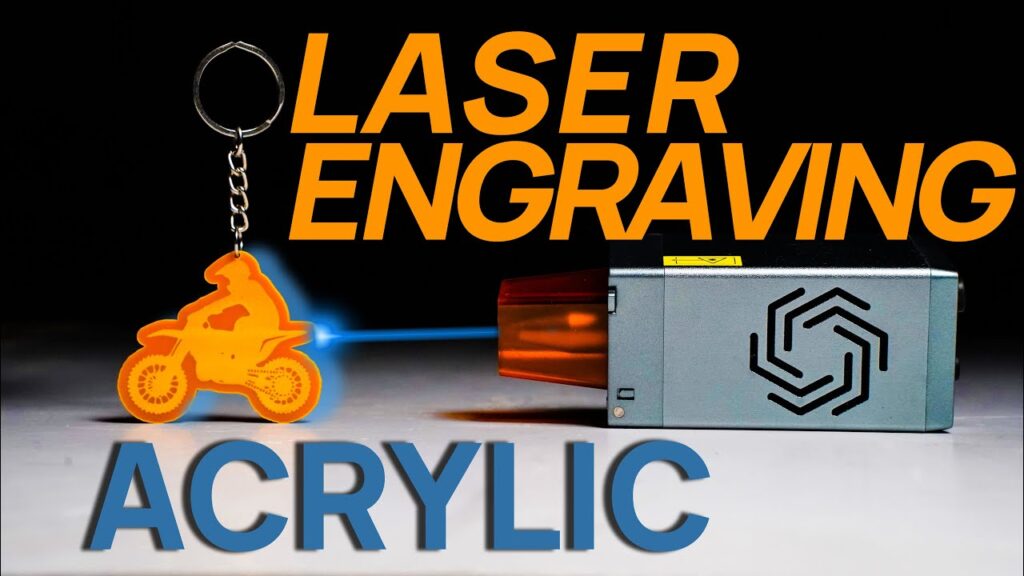

Double-color, dual-layer, or two-tone acrylic may be a flexible fabric for signage, grants, and enriching applications. It stands out among its peers because of the differentiation made between its layers of color when etching it with a laser. Learning laser etching twofold color acrylic will grow your workflow and deliver the best quality, well-qualified results. This article Double Color Acrylic for Laser Engraving will walk through how to set up and work laser frameworks on two-fold color acrylic to create an ideal comes about.

Understanding Twofold Color Acrylic Sheet

Two-color acrylic is composed of two acrylic sheets with particular tints; ordinarily, one lean-colored sheet sits on another lean-colored sheet that highlights straightforward or distinctive colored acrylic; when cut open, it uncovers both tints at once for an alluring two-tone see.

Sorts of Twofold Color Acrylic Paint.

Opaque/Opaque layers

Double Color Acrylic for Laser Engraving include strong colors with striking visual effects; when illuminated from behind, they deliver striking results with sensational Profundity of field and a plenitude of differentiation and vibrance. Clear/Opaque: The best layer is misty, whereas its lower layer—made up of straightforward acrylic—produces staggering impacts when lit backdrop illumination.

Translucent/Translucent Acrylic:

Each Twofold Color Acrylic fabric layer has semi-transparent qualities for more unobtrusive differentiation, making this perfect for laser etching applications.

Securing the Fitting Fabric Select twofold color acrylics of adequate weight and fitting colors that suit the extent at hand. Thickness regularly ranges between 1/16 inch and 1/4 inch for ideal etching. Be attentive to impersonation acrylics, which contain flaws that might prevent etching forms.

Cleansing Acrylic

Double Color Acrylic for Laser Engraving Sometime recently, starting etching, wiped down the surface to kill fingerprints, and cleaned any other collected particles. A nonabrasive cleaner combined with delicate fabric should do the work, as this guarantees scratch-free etching for a consistent and straightforward result.

Plans Basis

Beyond any doubt, it works with a laser etching computer program as well as fitting inside its measurements on an acrylic sheet.

Vector Illustrations Permit you to deliver nitty gritty etching, where conventional pictures might get to be as well pixelated for exact etching work.

Plan Contemplations (AC/AB 63B1): Recently, when planning on acrylic, consider its thickness and etching profundity prerequisites for complex plans that might require alterations for exact and proficient results.

Designing Your Laser Etcher

Alter the Acrylic Sheet: Orchestrate and secure the acrylic sheet on the bed of the laser for precise etching to come about. Adjust it concurring to enlighten your laser in arranging to ensure the exactness of the etching.

Concentrate the laser pillar on the acrylic surface for precise and clean etching. With Laser Etching Strategies

Setting Up Laser Etching Materials

Each laser etching fabric may require one-of-a-kind settings; if it’s not too much trouble, take after your manufacturer’s suggested alterations when making alterations to laser settings. A few common settings to be beyond any doubt incorporate:

Control:

For a more profound incision, increase power settings appropriately. Vityaz: Tweak speed settings depending on trouble and estimate of etching extent, with slower speeds announcing more noteworthy detail in the work made.

Recurrence For CO2 lasers, recurrence can have a sensational effect on etching quality; higher frequencies regularly abdicate more exact etching.

Approval and Testing

To refine your settings, test them utilizing a few double-colored acrylics to confirm them from when the last generation started. Doing this could save waste material while guaranteeing the most excellent conclusion possible for clients.

Etching Handle

Engraving Profundity, It is pivotal that etching Profundity be controlled to realize uniform color without cutting through it,

whereas layer differentiation ought to be exact and unmistakable without etching demolishing its visual aesthetics.

Cooling and Post-Processing After etching acrylic, allow it to cool for some time before taking steps for post-processing to halt distortion or distortion of its shape.

Once cool, utilize a straightforward brush or compressed air blower to clear absent defensive film or buildup on its surface as well as any regions where etching happened.

Investigating Common Issues [Connect]

Uneven Engraving. Want To Illuminate Uneven Etching Issue?

For arrangements on uneven etching issues or conflicting Profundity or uneven etching., guarantee acrylic is accurately adjusted, the laser is in the center, power/speed settings are balanced as required,

and any extra marks or burn marks expelled sometime recently beginning work on etching the surface. Conflicting Profundity Engraving/Uneven Etching for acrylic surfaces

Issue: Dull or burned zones within the region of inscriptions.

Solution:

Diminish control or increment speed to diminish the abundance of warmth while ensuring adequate ventilation to dodge clean and smoke from being delivered during etching preparation.

(TIP # 22 / 22-1) For shaded colors. (TIP #22) ….

Issue Colors show up sporadic or conflicting.

Arrangement To accomplish the craved differentiation in the color, survey and clean the acrylic altogether before etching it.

Guarantee High-Quality Acrylic Buy high-quality double-colored acrylic for ideal etching results and life span. Keep Your Laser Focal Point Clean

Your laser focal point is frequently used to ensure steady etching and guarantee quality administrations.

Test With Diverse Settings To achieve the perfect setup for your acrylic format,

try playing around with different control, speed, and recurrence settings.

If you have recently jumped in and begun your last work, utilize scrap materials such as acrylic to hone and sharpen your strategies and setup.

This way, you’ll be way better equipped and more capable.

Conclusion

Laser etching utilizing double-color acrylic offers an inventive strategy to make excellent, high-end plans.

You may accomplish an awesome payoff that brings out its two-tone impact by understanding both materials and your artwork’s planning handle and laser settings,

fine-tuning, and acing this one-of-a-kind etching strategy.

Make utilize of the proposals and rules given in this in arrange to pick up information in etching twofold color acrylic

to produce amazing outcomes that make an impression explanation of almost your work –

be it personalized awards, signage, or enhancing things; this method will stand out among clients or gatherings of people alike!

Pingback: TL Phone: The Next Big Thing in Mobile Technology -